What if you could store Copenhagen's entire energy consumption in the Round Tower?

It may sound like futuristic music, but if you use liquid hydroxide salt – caustic soda or, in everyday language, drain cleaner – as a storage medium, it can be done. This is according to Ask E. Løvschall-Jensen, CEO of Hyme Energy.

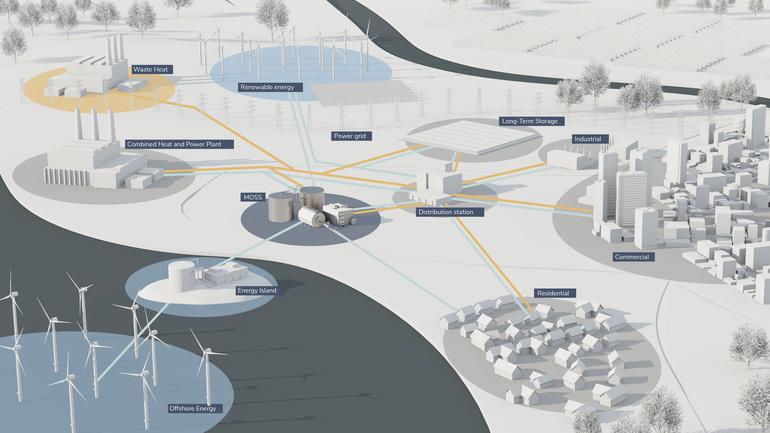

The company is part of the MOSS project, which, with support of 13.2 million DKK from the EUDP and a total budget of 24.7 million DKK, will demonstrate the potential of drain cleaner in a pilot energy storage facility at DIN Forsyning in Esbjerg. The first sod for the facility will be laid in the summer of 2023, Energy Cluster Denmark writes in a statement.

- Efficient storage of renewable energy is about us having access to green electrons when the need arises. We can do this by storing renewable energy in liquid salt. When we shift wind turbine power, we can supply electricity and heat cheaply in a limited area with our salt storage, and we can move the renewable energy to the times when it is in demand, says Ask E. Løvschall-Jensen.

A tank that is ten meters high and twenty meters in diameter can store enough salt to store 1 GWh. With a 100 MWt turbine in operation, such a tank will deliver annual CO2 reductions of up to 110,000 tons by replacing fossil cogeneration sources.

Strong base

The salt-stored energy from the MOSS plant produces steam, which can be used to generate electricity or district heating via a steam turbine. The liquid salt on which the plant is based is an effective storage material, but it is also strongly alkaline. The components must therefore be able to withstand operation at high temperatures and under corrosive conditions. It is a challenge that project partners are joining forces to take on.

The project partner SAN Electro Heat A/S is supplying a heater that converts the green electricity into heat in the salt storage.

- The challenge is that sodium hydroxide is corrosive, and this places high demands on the choice of materials and construction of the heater when the liquid salt is to be heated from 350 °C to 700 °C. We have come a long way with a design that will be tested in contact with the liquid salt, so we are ready to deliver a solution for the demonstration plant, says Peter Munk, Technical Sales & Quality Manager at SAN Electro Heat A/S.

At DIN Forsyning in Esbjerg, which will house the plant, the most important task is to ensure heat for consumers - now and in the future.

- We have the support of our owners for innovative initiatives and want to be a significant player in the energy market of the future. That is why we have committed ourselves to the demonstration project, which could become a significant technology for the future regulation of the energy system. DIN Forsyning is looking at compact energy storage that can both ensure flexibility in relation to the electricity system and be future peak and emergency loads in the heat supply, when we are to be able to deliver fossil-free heat by 2030 at the latest, says Kim Stenholdt Madsen, senior project manager at DIN Forsyning.

First in the world

The pilot plant will be the first of its kind in the world. According to Ask E. Løvschall-Jensen, the plan is to roll out the storage in Denmark first, and then launch it as a product in the global market.

- The demonstration plant in Esbjerg will be our litmus test. It has been built in the right size, and will ensure that in the long term we can deliver frequency services and stability as we know it from combined heat and power plants, for example. The potential is enormous, and we are looking forward to starting construction, he says.

The partners behind the project are: DIN Forsyning, Alfa Laval Aalborg, KIRT X THOMSEN, SAN Electro Heat A/S, SULZER, Seaborg, Aalborg University, Hyme Energy and Energy Cluster Denmark. The project is expected to be completed in 2024.

amp

Text, graphics, images, sound, and other content on this website are protected under copyright law. DK Medier reserves all rights to the content, including the right to exploit the content for the purpose of text and data mining, cf. Section 11b of the Copyright Act and Article 4 of the DSM Directive.

Customers with IP agreements/major customer agreements may only share Danish Offshore Industry articles internally for the purpose of handling specific cases. Sharing in connection with specific cases refers to journaling, archiving, or similar uses.

Customers with a personal subscription/login may not share Danish Offshore Industry articles with individuals who do not themselves have a personal subscription to Danish Offshore Industry.

Any deviation from the above requires written consent from DK Medier.