Engineers from Aarhus University, together with the company R&D Test Systems, will develop the new, larger and much more advanced test benches for nacelles of the future. The goal is to enable the wind industry to accelerate the development of the next generation of giant wind turbines.

The project has received 10.3 million DKK in support from EUDP (The Energy Technology Development and Demonstration Programme) and will strengthen Denmark's technological leadership position within wind technology.

- The wind industry's ability to innovate and develop depends largely on the technological possibilities for testing the ever-larger wind turbines, and we have a head start in Denmark in this regard. We want to make the impossible possible and design a test bench that is completely out of the ordinary, where the size itself poses some complex engineering challenges, says Lasse M. Stephansen, Team Lead, Civil Engineering at R&D Test Systems.

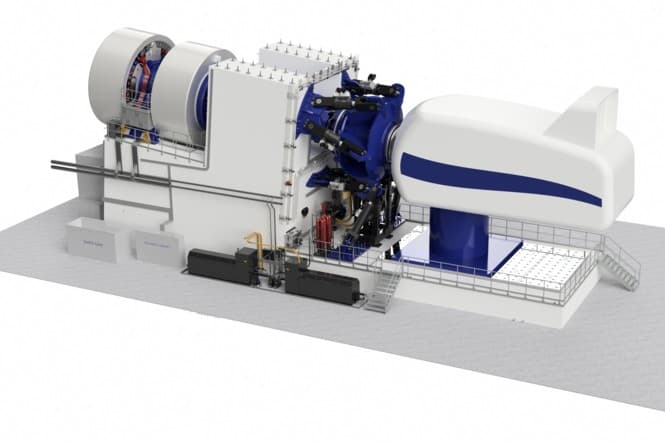

He explains that the test benches should be used by wind turbine manufacturers to test the performance and lifespan of the nacelles. In the project, the engineers from Aarhus University will develop the design and the first prototype of the test bench.

Great forces at stake

In the coming two years, the university's concrete experts will therefore be busy in the building laboratory, where they will find the most optimal design of a suitable test facility for nacelles.

The challenge is that the nacelles on the latest wind turbine concepts have become too large for the already enormous test benches we know today.

- The nacelles connect the wind turbine blades to the tower, and it is therefore absolutely crucial that we can test their durability. But now they have become too large, and we need a new type of test bench that can accommodate their enormous forces, says Lars German Hagsten, Associate Professor of Engineering, Aarhus University.

The new test bench will be cast in concrete with 500 points where the nacelle can be securely attached.

- We will use this test bench for repeatability and fatigue tests. We want to see how much the nacelle can withstand before it breaks, and this means that the test facility must be able to handle a very large total force impact, says Lars German Hagsten.

Must have a longer lifespan

The engineers also plan to embed measuring equipment in the test bench so that they can continuously see how well it is doing. This will make it possible to monitor wear and thus optimize maintenance.

- A test bench with these dimensions is enormously expensive, and therefore we would like to make it possible to increase its lifespan, says Lars German Hagsten.

The lifespan of a test bench is crucial to its competitiveness on the global market, and R&D Test Systems therefore has high expectations for the collaboration with Aarhus University.

- When our customers are going to invest large sums of money in a test bench, they naturally look at its lifespan. We need highly specialized knowledge of concrete structures if we are to keep up with developments and demand in the wind industry, and our collaboration with Aarhus University is of great importance here, says Lasse M. Stephansen.

esl

Text, graphics, images, sound, and other content on this website are protected under copyright law. DK Medier reserves all rights to the content, including the right to exploit the content for the purpose of text and data mining, cf. Section 11b of the Copyright Act and Article 4 of the DSM Directive.

Customers with IP agreements/major customer agreements may only share Danish Offshore Industry articles internally for the purpose of handling specific cases. Sharing in connection with specific cases refers to journaling, archiving, or similar uses.

Customers with a personal subscription/login may not share Danish Offshore Industry articles with individuals who do not themselves have a personal subscription to Danish Offshore Industry.

Any deviation from the above requires written consent from DK Medier.