The offshore wind farms of the future must not only be larger and consist of even taller and more powerful wind turbines; they must also be cheaper and more efficient in operation. This must be ensured, among other things, through shorter downtimes when the turbines fail.

- From 1990 to today, we have reduced CO2 by 20 percent. Over the next 30 years, we must reduce it by a further 60 percent. This means that we must be three times as aggressive to achieve our goals, and that is a fundamental change. Therefore, servicing wind turbines must be industrialized, says Lars Holm Nielsen, Head of R&D Service Operations at Siemens Gamesa.

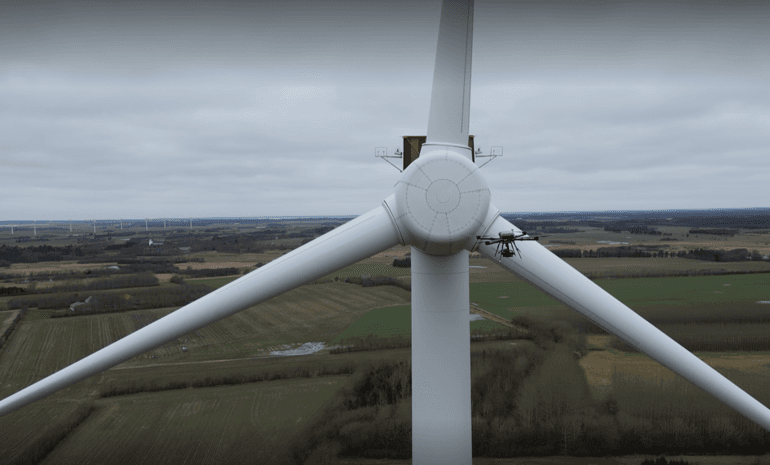

Automated drones are a good way to industrialize part of that, and a group of partners consisting of Siemens Gamesa, ESVAGT, Upteko and the University of Southern Denmark under the auspices of Energy Cluster Denmark are working to solve this, the latter said in a statement.

The innovation project Flexible Offshore Drone for Wind (FOD4Wind) will significantly reduce downtime, CO2 emissions and service costs by placing drones on the wind farm's wind turbine service vessel – a so-called SOV – and programming the drones to deliver spare parts and tools directly from the vessel to the technicians in the turbine.

Today, spare parts are transferred by SOV, which even with careful planning takes a long time and will only take longer as the farms get larger.

- Can we replace sailing with drone flights from larger ships, you save many of the trips around the wind farm. There is great potential in this – both in time and in CO2 emissions, says Benjamin Meinertz, partner at Upteko.

Upteko programs the fully automatic drones, which will take off from Esvagt ships and transport equipment and tools to the nacelle of the offshore wind turbine. Drones will also be able to perform other tasks from the ship – something that Esvagt sees great potential in.

- Parcel deliveries have great potential, but in addition, the innovation project can also help move the inspection of turbines from being a manual process to being automated. This will provide a faster and much more accurate measurement, says Nils Overgaard, Head of Special Projects at Esvagt.

Can significantly reduce costs

If you succeed in fully autonomous wind turbine inspection and package deliveries of, for example, tools using drones and fixed charging stations on SOVs, the effect will also be significant.

The drones can be used for several different purposes and will reduce both costs and CO2 emissions. Based on 70 installed charging stations with drones, the effect will be reduced downtime by 12,250 hours annually in 2030, 13,000 tons of CO2 reduction, increased energy production by 39,200 MWh, reduced service costs by 424 million. DKK and increased employment of 180 employees.

- Our business case is positive – both when it comes to deliveries and perhaps also inspection of offshore wind turbines. By using drones for maintenance of our wind turbines, we can reduce both our costs and our environmental footprint, says Lars Holm Nielsen.

The project is supported by the Energy Technology Development and Demonstration Programme (EUDP) and has a total budget of DKK 17 million. It has previously been supported by the EU's Regional Fund. It runs until the end of 2024.

amp

Text, graphics, images, sound, and other content on this website are protected under copyright law. DK Medier reserves all rights to the content, including the right to exploit the content for the purpose of text and data mining, cf. Section 11b of the Copyright Act and Article 4 of the DSM Directive.

Customers with IP agreements/major customer agreements may only share Danish Offshore Industry articles internally for the purpose of handling specific cases. Sharing in connection with specific cases refers to journaling, archiving, or similar uses.

Customers with a personal subscription/login may not share Danish Offshore Industry articles with individuals who do not themselves have a personal subscription to Danish Offshore Industry.

Any deviation from the above requires written consent from DK Medier.