It's about safety at CCUS, says IKM Ocean Team's CMO Bonna Ravn Thomsen, already when we make the interview agreement about something that the Esbjerg company is working on, namely the safety of carbon capture, utilization and storage (CCUS).

- We have to ensure that it doesn't end up with the CO2 that is stored leaking out of the well, so that the North Sea turns into sparkling water, where the bubbles rise, explains Bonna Ravn Thomsen on the phone about what would be close to a worst-case scenario for the technology that will help secure Denmark's 2030 climate goals.

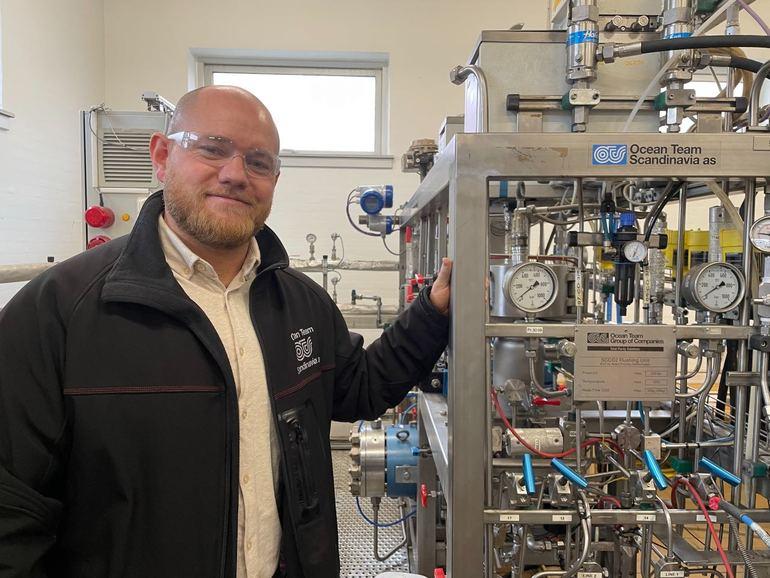

How to ensure that the CO2 stays down in the abandoned oil and gas wells is something that IKM Ocean Team's innovation manager Benjamin Lorentzen is working intensively on.

- How do you do this safely in concrete terms, was the question when we were involved in the precursor to Project Greensand. We helped to make realistic experiments using existing infrastructure in the North Sea, says Benjamin Lorentzen and elaborates:

- We built a test system that was designed to fit equipment that we were already using. It is a custom-built reactor where we can simulate the conditions on a small scale that will be in the wells. We got the salt-brine that is in the reservoir out in the North Sea, CO2 and tested it under high pressure at different temperatures, says the innovation manager.

Together, the CO2, the salt-brine and the pressure become a cocktail that you don't know how the steel, concrete and other materials in the wells react to. It is a cocktail that only becomes more complex because the CO2 contains different chemical impurities depending on which source in the industry it comes from.

- These are complex chemical processes, and it is important to know what the parts and materials look like after they have been exposed to this mixture, says Benjamin Thomsen, taking a short pause before reporting the result:

- All parties around the table were actually surprised by how aggressive the corrosive was against the materials. You have to consider very carefully which materials you use.

New collaboration

While IKM Ocean Teams did not become part of Project Greensand, the work continues in the COLLATE association, which stands for CO2 liquid laboratory testing. COLLATE consists of partners INEOS, Wintershall Dea, GEO, Energy Cluster Denmark and DTU.

There are many questions that need to be clarified on the way to making CCUS a business that can help the environment on a large scale. There is already talk in the offshore industry that such a large scale will include a pipeline from heavy German industry all the way to Esbjerg and further out to the large reservoirs in the North Sea's subsoil.

- The condition for making a big business out of it, so that it can become a real green solution, requires a massive investment in the entire infrastructure. This again requires a lot of safety. What materials should be used for a pipeline, and nothing that destroys biodiversity in the North Sea must be released. The CO2 may be able to stay there for 10,000 years, says Benjamin Lorentzen.

But there is also the whole part about the CO2 being able to be retrieved again and used, for example, for PtX.

- The next step will be to develop a filling station so that the CO2 can be used again, it says.

IKM Ocean Teams makes test loops, this means that this development work can be carried out in a safe way.

- Our main goal is to make models that show - how materials react over many, many years with our test equipment. We can stretch the data so that we can see that CCUS will not be a problem for our children one day. It is scientific data that comes out of it, he says.

Will sell services and hardware

The test loops at IKM Ocean Teams are also a trade secret, because it is the test facilities themselves that will become a business one day.

- It is our hope that we can position ourselves at the forefront of making a commercial business out of it together with our partners. We build the hardware that can generate the data that needs to be used. Because concrete experiments are necessary. This way you can precisely dimension which materials need to be used without overdimensioning, so that, for example, too much steel is not used in a pipeline for CO2, explains Benjamin Lorentzen.

The head of innovation already knows who will be IKM Ocean Team's customers in this area.

- We would like to sell both the service and the analysis equipment, for example, to the research community, universities and industry. Then you can also simulate how gas, hydrogen and CO2 react in our test loops, says Benjamin Lorentzen, while he is standing at one of IKM Ocean Team's test facilities, which are so not allowed to be photographed or described in this article.

The equipment can also be used in connection with PtX in addition to CCUS. The innovation manager would like to reveal a little about the facility.

- Above all, our solution is neither large nor expensive. You will be able to build 100 and generate a much greater bandwidth of data, concludes Benjamin Lorentzen.

Text, graphics, images, sound, and other content on this website are protected under copyright law. DK Medier reserves all rights to the content, including the right to exploit the content for the purpose of text and data mining, cf. Section 11b of the Copyright Act and Article 4 of the DSM Directive.

Customers with IP agreements/major customer agreements may only share Danish Offshore Industry articles internally for the purpose of handling specific cases. Sharing in connection with specific cases refers to journaling, archiving, or similar uses.

Customers with a personal subscription/login may not share Danish Offshore Industry articles with individuals who do not themselves have a personal subscription to Danish Offshore Industry.

Any deviation from the above requires written consent from DK Medier.